IRTIS-2000 SV, SN Industry - high precision digital thermograph

IRTIS-2000 SV, SN Industry

Is designed for thermal imaging in manufacture of microelectronics, for non-destructive thermal imaging of different objects in industry and construction. IRTIS-2000 SN in addition to SV model is designed for measurement of very high temperatures and is working in particularly tough conditions.

Technical specifications:

- Spectral range - 3-5 µm (the ability to control the temperature of the absorbing and reflecting surfaces - glass, porcelain, tiles)

- Sensitivity to changes in temperature at 30°C over the entire field of view - 0.05оС (0.02оС)

- Field of view - not less than 25x20о

- Instantaneous field of view - not more 1.2 mrad

- Measured temperature range - from - 60оС to +300оС (Irtis 2000 SV1), from - 50оС to +500оС (Irtis 2000 SV2); from - 60оС to +1000оС (1700оС, 2000оС - special editions) - Irtis 2000 SN.

- Outside temperature range - from - 40оС to +60оС

- Measurement error of the absolute temperatures across the entire field of view - ±0.5оС

- Temperature heterogeneity across the field of view - not more than ± 0.1оС

- Temperature drift from frame to frame - not more than ± 0.1оС

- Number of elements in a line - 640

- Number of lines per frame - 480

- Total scanning resolution - 640x480 (307200 points of measurement)

- Framing time (3 scanning speed) - not more than 0.8 s., 1,6 s., 3,2 s.

- Line scanning mode

- Operating time using the rechargeable battery - up to 8 hours

- Weight - 1.4 kg

- Dimensions - 92x157x210 mm

- Built-in laser pointer - 1 mW

- Communication protocol with computer - ethernet

- Warranty period - 24 months

Complete set of delivery Irtis 2000 SV, SN (SV - Industrial control, SN - Industrial control in particularly tough conditions):

- Thermograph «Irtis 2000 SV, SN» - 1

- Software - 1

- Laptop with installed software - 1

- Rechargeable battery - 2

- Power charging unit - 1

- Set of cables - 1 set

- Tripod - 1

- Carrying bag - 1

- Operating manual, technical documentation - 1 set

Accessories (optional, at extra charge):

- Hardware and software package for creating panorama thermograms

- Built in videocamera 640x480

- Wi-Fi module for thermograph

- Mobile processor unit on the Android OS with Wi-Fi wireless connection module for thermography

Fields of application of computer thermography:

1. Power resources saving

Thermography saves power resources and is a reliable mean of eliminating heat losses.

Using IR-methods of control to see defects of buildings and roofs and their repair timely before the big detriment is playing the great part in rise of power effectiveness and makes it possible to save investments at equipment and materials.

The discovery of water condense, defective concrete panel, leakage of warmth from seams of buildings makes it possible to localise defect and take all needed steps for its removal.

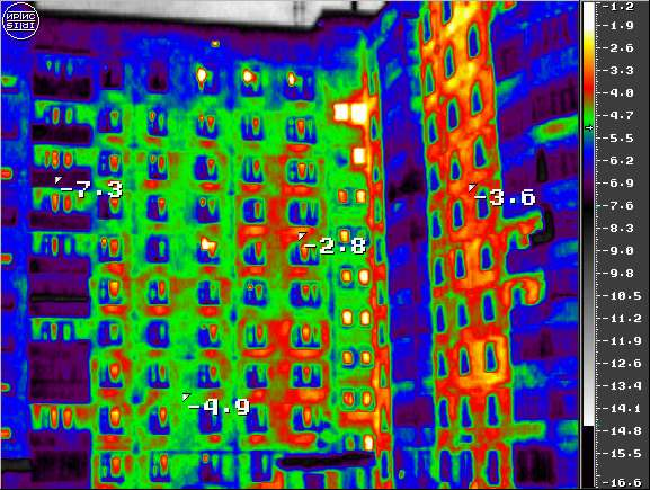

Violation of thermoisolation of building panels:

|

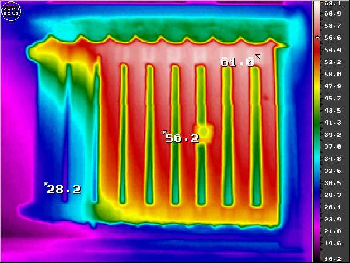

Obstruction of hot-water radiator sections: |

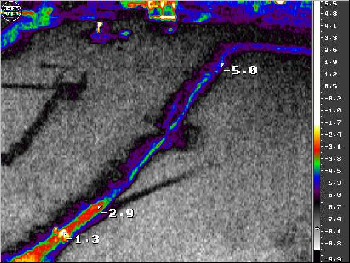

Breaking of underground heating: |

|

|

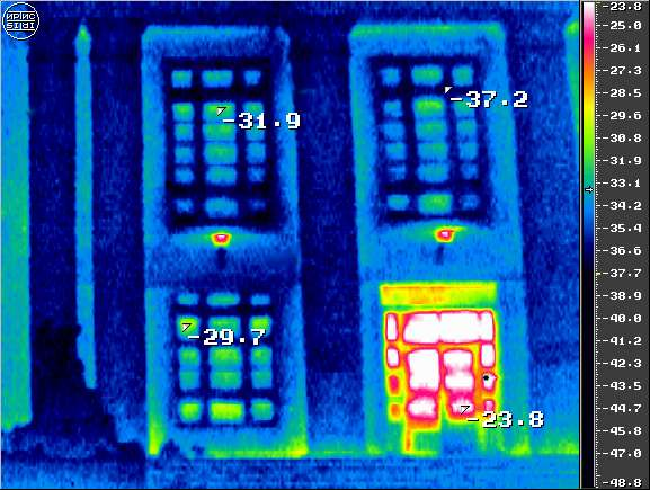

Heat leakage from junction on wall building:

2. Power industry

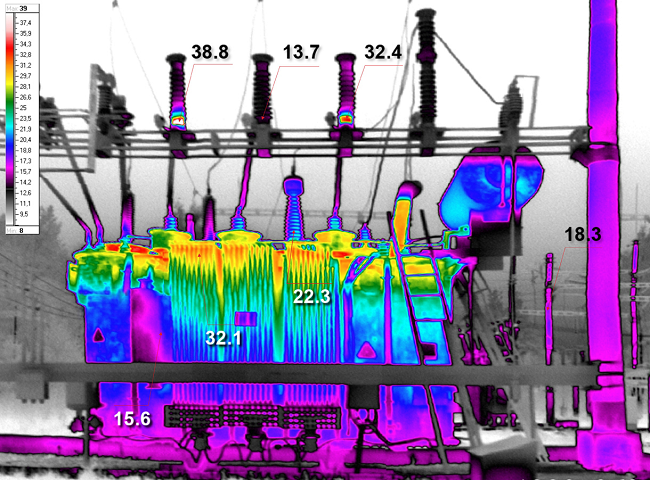

In the power industry thermograph can be used over the entire cycle of generation and distribution of electric power: from power stations and high-voltage transmission lines to substations and the equipment of power consumers.

A thermogram will quickly and clearly reveal malfunction long before minor faults grow into major operational problems, because inspection is carried out under normal operating conditions - measurements are non-contact.

Early detection of faults facilitates planning of maintenance and repair and procurement of spare parts.

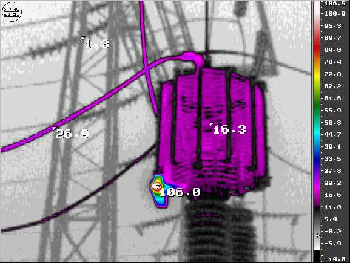

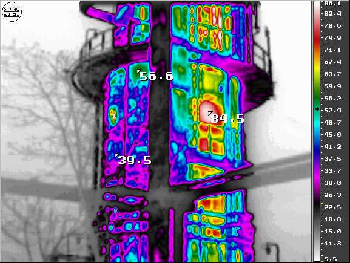

Local heating of high voltage transformer:

|

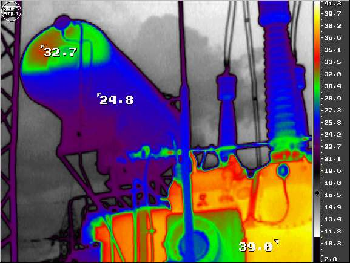

Oil level determination in transformer's tank: |

Short circuit of generator's stator: |

|

|

|

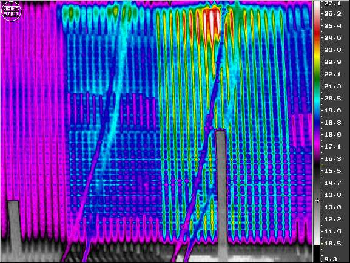

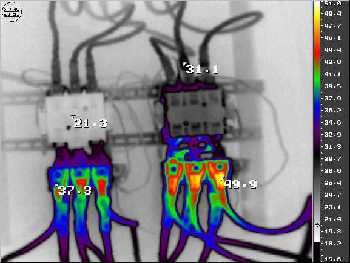

Overheating of contact because of bolted-type |

Defective contact of high frequency rejector: |

|

|

3. Industry

Thermography can be used for periodic inspection of heat-resistant isolation and uninterrupted operation of thermal and drying stoves, kilns, hot cisterns, repository scoops, isolation of conduits, dryers, boilers.

Thermography can help to detect conductor leaks, isolation defects of distributive networks, condense pots.

Thermography makes it possible to discover underground leaks of conduits.

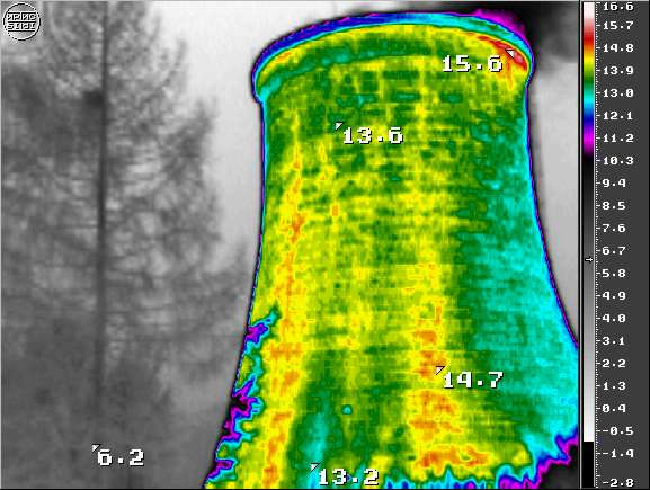

Inside breach of cooling tower wall:

|

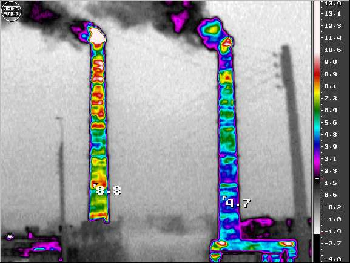

Thermo-control of chimneys: |

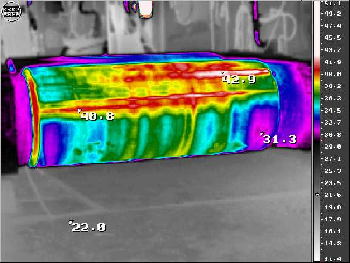

Non-uniform heating of rolling mill rollers: |

|

|

|

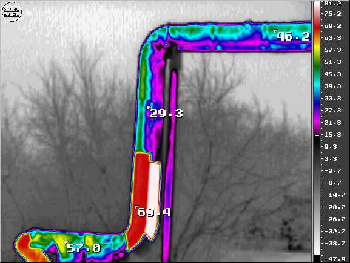

Defective thermo-isolation of overground pipeline: |

Violation of furnace of chemical synthesis column: |

|

|

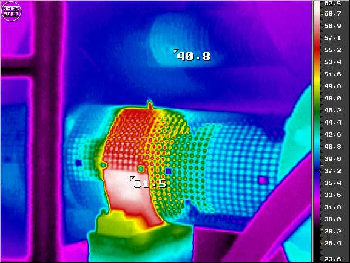

4. Machine building

IR-method can control:

- gear transmissions,

- shafts,

- wedge-belts,

- pulleys,

- sprocket drive,

- conveyers,

- air compressors,

- vacuum pumps,

- couplings.

The advantage of the IR-thermograph during mechanical equipment control is saving time, because after place overheating definition you can easily determine need in repair.

The thermograph with research of vibration and bolt-impulses defects can widen effectiveness of thermography control.

|

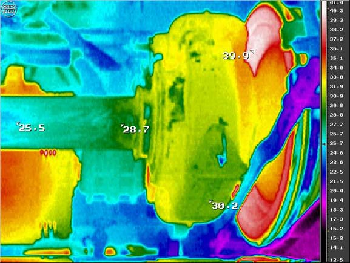

Metro rolling-stock transmission testing: |

Different pressure in cylinders of compressor: |

|

|

|

Overheating of collar bearing of electric motor shaft: |

Thermo-control of a component during laser hardening: |

|

|

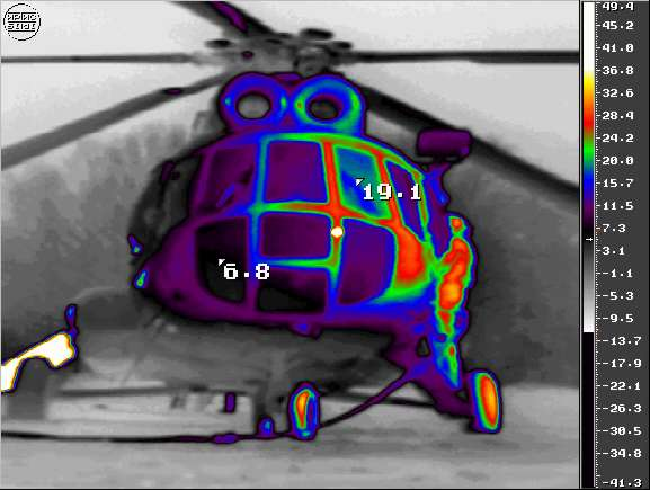

Testing of cockpit containment of helicopter:

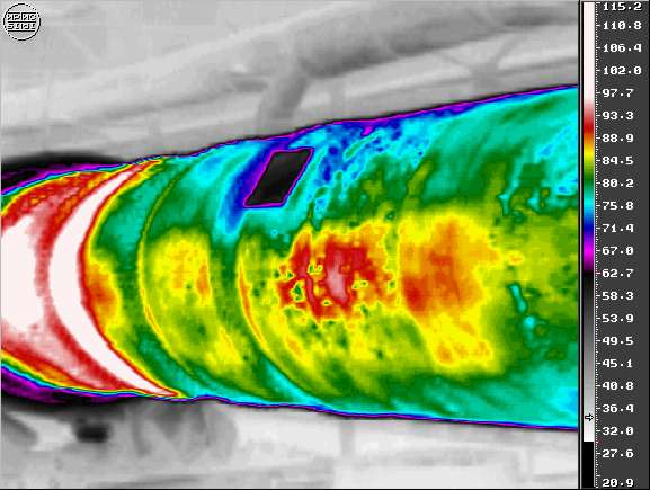

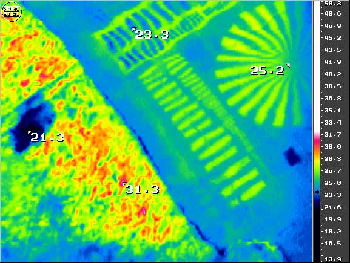

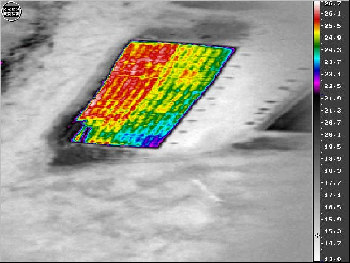

5. Non-destructive testing

Application of thermography for non-destructive testing gives possibility to solve problems that can’t be solved using any other methods.

For example:

- cement kiln testing during its functioning,

- searching for defects in panels of solar batteries,

- diagnostics of aircraft jet engines turbine blades,

- revealing of micro cracks and inconformity of metal structures.

Way of thermo-control helps to discover defects when any other method failed.

Infringement of the cement furnace lining:

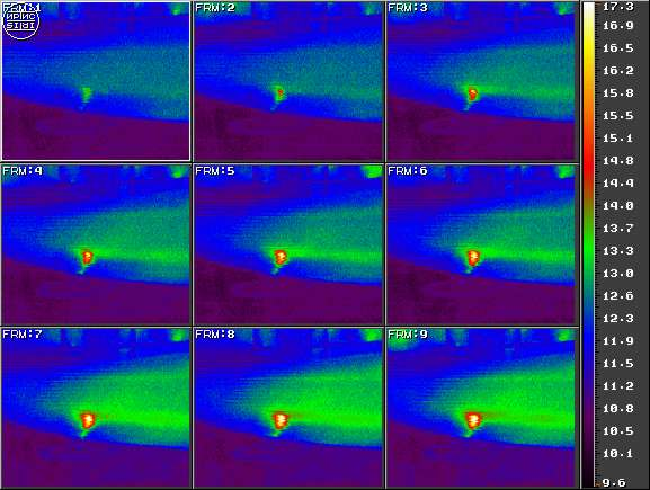

Detection of mictocracks in the blade of the helicpter at vibration:

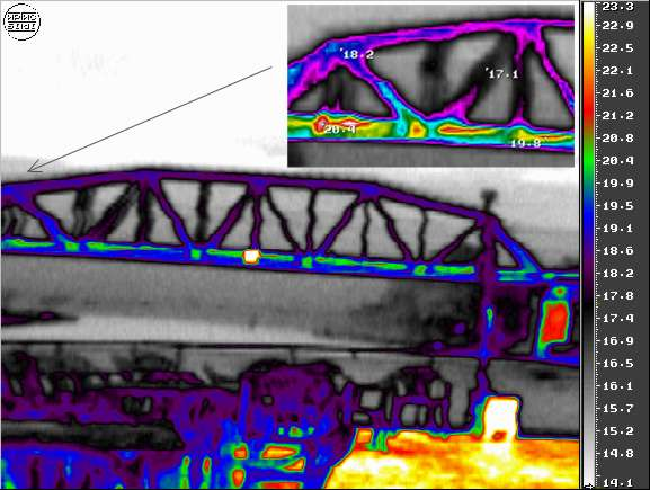

Overheating bolt fixture of the bridge after pass of a train:

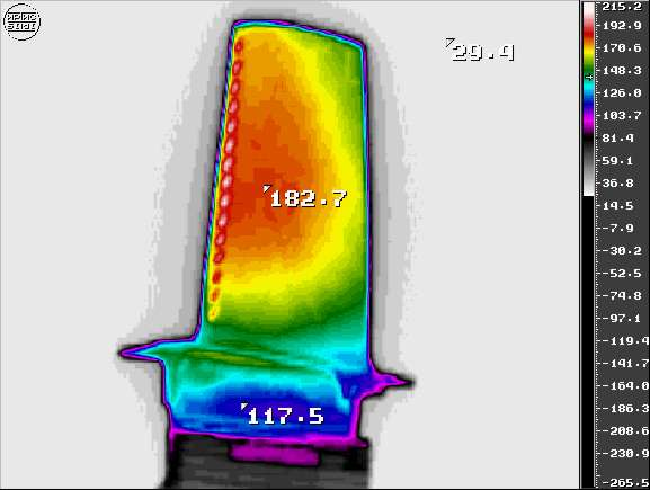

Thermal control of turbine blades of jet engines:

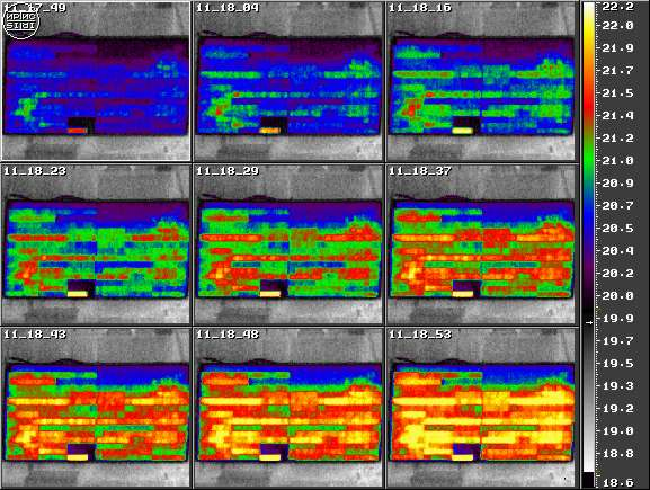

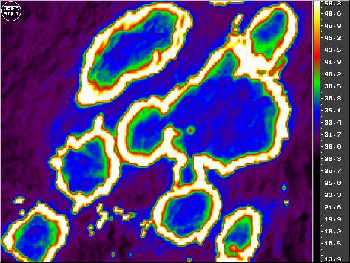

Revealing defects of panels of solar batteries:

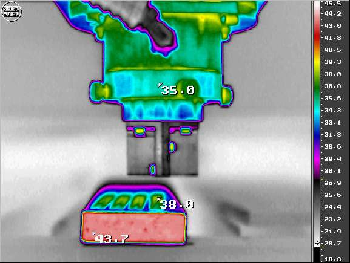

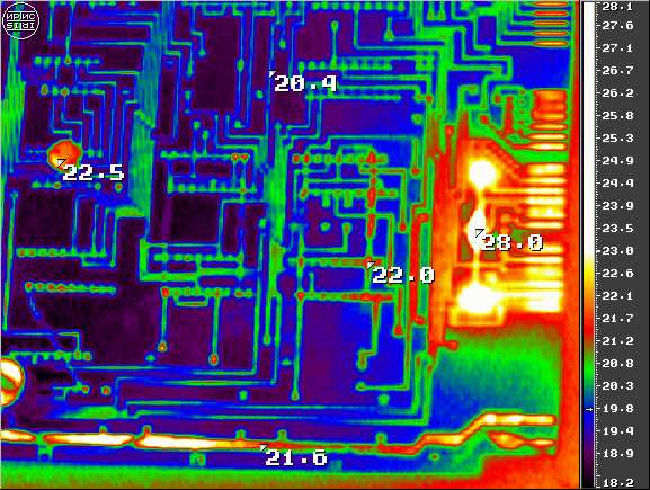

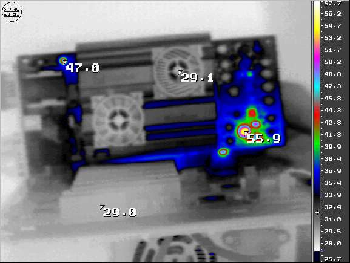

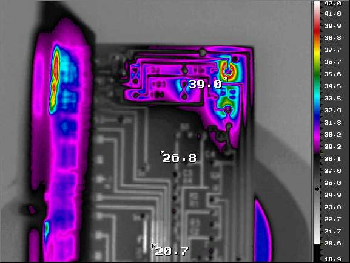

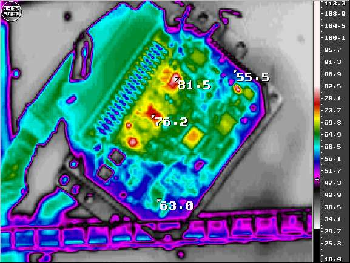

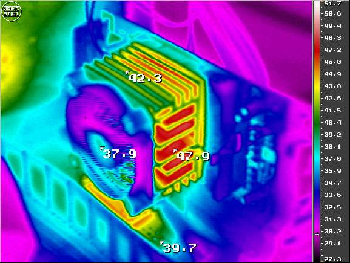

6. Electronics

Application of thermal testing methods gives possibility to estimate efficiency of printed circuit board or microchip quickly and qualitatively and saves time and investments.

Using of thermography methods in electronics helps:

- in revealing defects of printed circuit boards,

- in estimating of the functioning of heating elements,

- to find short circuits,

- to find non-working elements and spots with high resistant of soldering.

Method of thermo-control allows to model and develop high efficient cooling systems and estimate efficiency of their functioning.

Application of thermal testing methods gives possibility to estimate efficiency of printed circuit cards or microchips quickly and qualitatively and saves time and investments.

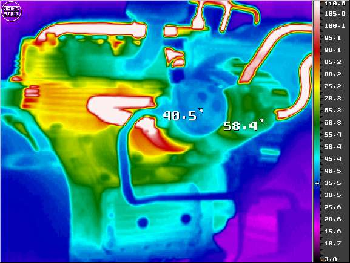

High resistance of a soldering:

|

Working off of thermal operating modes of the printed circuit card: |

Overheating of resistor because of incorrectly chosen power: |

|

|

|

Overheating of block of fuses of a car: |

Check of overal performance of cooling syste: |

|

|

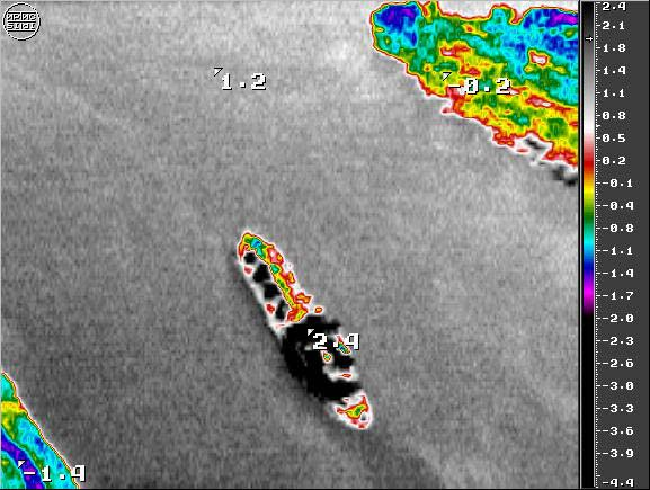

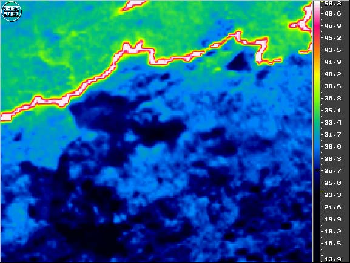

7. Aero-thermographic observations:

A number of know-how applied in a design allows to achieve the high repeatability of geometry of the consecutive frames, uniform sensitivity of temperature field of the frame and qualitative photorealistic thermograms.

It enables to make panoramic thermo-images, and also allows the realisation of aero thermal scanning:

|

|

|

|

For any questions you can contact us by live-chat in the lower right corner of the screen

Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Skype: tenmed1

Phone: +79264190710